ONLINE PARTS STORE

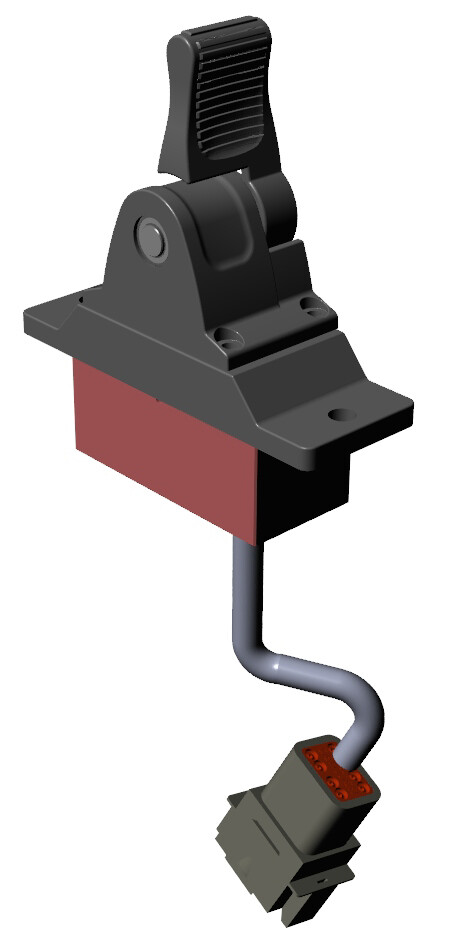

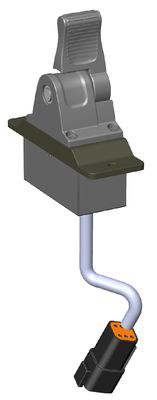

Faber-com MAPL PWM Joystick

$670.00

PWM Frequency

Enter your text

Minimum Current

Enter your text

Maximum Current

Enter your text

LEVER

Supply Voltage

1

Product Details

Faber‑com MAPL / MAP (PWM) Joystick — PWM Output Variant (MAP‑PWM)

Product Overview

The MAP (MAPL / MAP‑PWM) joystick is a single-axis, electronic control device that generates PWM (Pulse Width Modulation) output signals directly to drive proportional solenoid valves. It is part of Faber‑com’s family of joysticks capable of directly controlling hydraulic valves without an intermediate amplifier. Its design is modular and configurable to suit a variety of industrial and mobile hydraulic applications.

Key Specifications & Features

- Output Type

Dual PWM outputs (A + B), one for each direction of travel, proportional to lever movement.

Capable of driving two solenoid coils directly.

- Maximum Current

Up to ~2.5 A per output (or combined) depending on version. Adjustable Parameters

- • Minimum and maximum current levels for each direction

• Rise and fall ramp timing (0.1 to 25.0 s in many variants)

• PWM frequency tuning (50 to 300 Hz typical)

• Output shaping: linear or parabolic response curves

- Construction & Sensing

Employs redundant Hall effect sensors to detect joystick movement relative to a permanent magnet. The non‑contact sensing ensures minimal wear and consistent performance.

- Programming & Configuration

All operational settings are programmable through a serial interface (e.g. via the SepSim software and AISR adapter).

- Electrical / Mechanical Properties

• Supply Voltage: 10–30 VDC typical

• Operating Temperature: –40 °C to +70 °C (or depending on specific variant)

• Lever Travel: ±26° mechanical deflection (approximately)

• Connector / Cable: Typically a 20 cm cable terminating in a Deutsch connector (e.g. DT04‑8) or variant depending on model.

• Protection: The joystick electronics are typically sealed, and output circuits include short‑circuit protection.

Dual PWM outputs (A + B), one for each direction of travel, proportional to lever movement.

Capable of driving two solenoid coils directly.

Up to ~2.5 A per output (or combined) depending on version. Adjustable Parameters

• Rise and fall ramp timing (0.1 to 25.0 s in many variants)

• PWM frequency tuning (50 to 300 Hz typical)

• Output shaping: linear or parabolic response curves

Employs redundant Hall effect sensors to detect joystick movement relative to a permanent magnet. The non‑contact sensing ensures minimal wear and consistent performance.

All operational settings are programmable through a serial interface (e.g. via the SepSim software and AISR adapter).

• Supply Voltage: 10–30 VDC typical

• Operating Temperature: –40 °C to +70 °C (or depending on specific variant)

• Lever Travel: ±26° mechanical deflection (approximately)

• Connector / Cable: Typically a 20 cm cable terminating in a Deutsch connector (e.g. DT04‑8) or variant depending on model.

• Protection: The joystick electronics are typically sealed, and output circuits include short‑circuit protection.

Applications & Use Cases

- Direct driving of proportional solenoid valves in hydraulic systems (e.g. cranes, lifts, aerial platforms)

- Situations where minimizing external wiring and driver modules is advantageous

- Mobile machinery control panels where responsive, proportional control is required

- Environments that demand durability and reliability under varying loads, voltage, and temperature conditions

Save this product for later

Faber-com MAPL PWM Joystick

You May Also Like

Pre-order

FABER COM PISPR Joystick Programming Module

FABER COM PISPR Joystick Programming Module

Joystick Programming Module

$438.00

Pre-order

FABER COM JS JOYSTICK with Danfoss 1 push button

FABER COM JS JOYSTICK with Danfoss 1 push button

FABER COM JS JOYSTICK with Danfoss 1 push button

$1 425.00

Pre-order

46662_B SCANRECO Sticker for Handy PCU

46662_B SCANRECO Sticker for Handy PCU

Joystick Programming Module

$23.00

Display prices in:AUD

We Accept Visa & Master Card